For more than 50 years WAIBL has been known inland and abroad for top sprayers with optimal spraying technology. Our self-designed and developed machines are the result of the latest technology, first-class materials and the strictest quality controls.

The company

The right partner for professionals in orchards and vineyards

The manufacturing process not only takes into account the latest and highest quality standards, but also focuses on individual customer needs and desires. Thanks to valuable contacts with various experts in fruit and wine growing, we are always one step ahead in the field of appliance technology.

History

Waibl Sprayers – a family business with tradition.

Company founder Waibl Diethart, dealt already in the middle of the 60’s with spraying technology. His wife Christine is supporting it’s business since the foundation in Merano-Sinigo. His son Christian joined the business about 30 years ago.

Today, WAIBL, is one of the leading companies in this field and offers many years of experience and great expert advice.

The direct contact with the users and the farmers, meant that the company Waibl was always one step ahead and could always offer optimal and customer-oriented

Our strenghts

- All-round support from the beginning

- Many years of experience

- Additional equipment suitable for every user

- Constant test procedures in agricultural everyday life

Professional advice is a top priority at WAIBL, as the customer’s expectations should be fully met. The given information and ideas at the first meeting with a client, allow us to suggest the appropriate sprayer.

Optimum additional equipment for the specific use is the all-rounder for the precise and optimal use of the sprayer. Thanks to our many years of experience, we are able to consulate every one of our customers individually.

Prototypes are basically tested for at least one spraying period by a user directly in the agricultural everyday life and guarantee a professional development work. By analyzing the extracted information, the production of WAIBL SPRAYERS receives valuable information and the customer a perfectly engineered machine.

Innovations

The list of designed technical innovations is very long and has been copied several times by other manufacturers. Here is an extract:

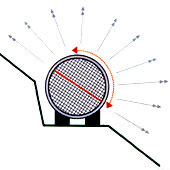

Rotatable fan for terrace cultivation.

Patent No. 480/A81 dated 06.01.1981

Double fan for even distribution.

Patent No. 1172926 dated 18.06.1987

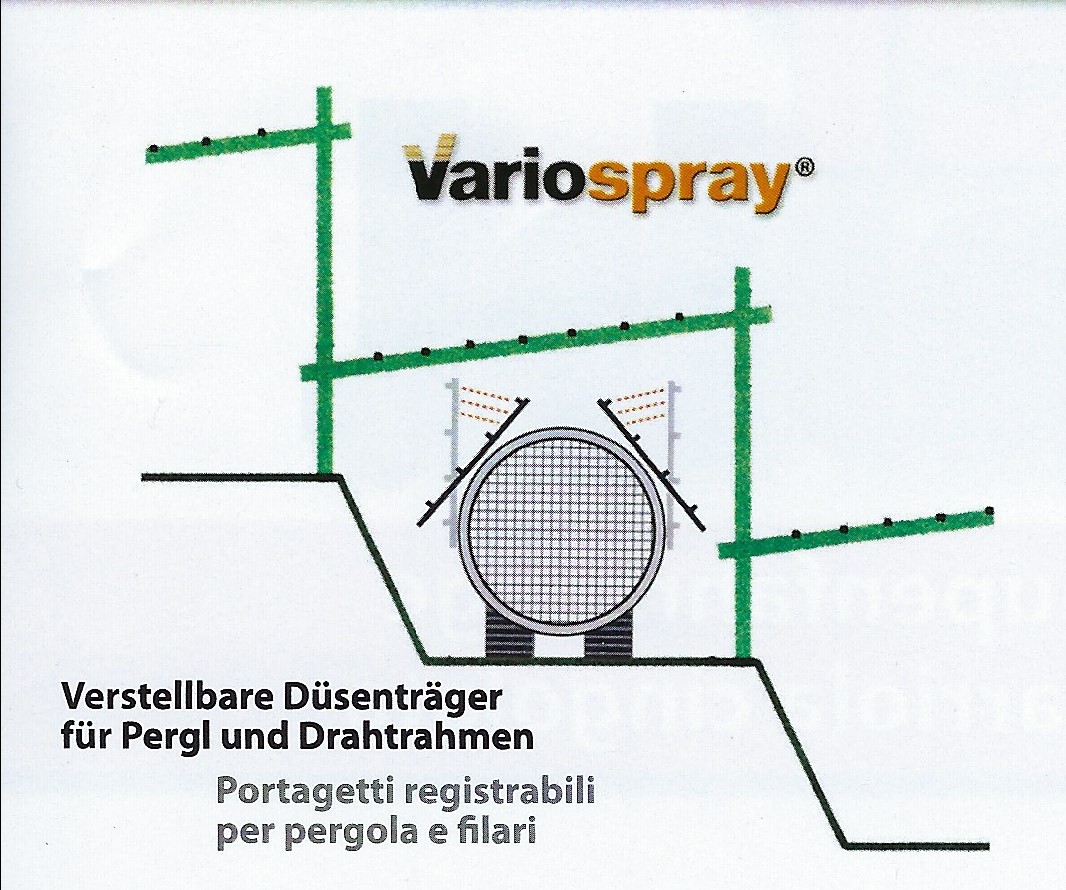

VARIO SPRAY

…developed in the late 80s

Oil – hydraulically adjustable nozzle holders enable one sprayer to spray various plant systems.

Flushing device

…developed in the early 80s

material box with mixing device and packaging cleaner

later EUREPGAP

valid from: 29. October 2004

mandatory since: 01. May 2005

today GLOBALG.A.P.

www.globalgap.org

Electrical fittings

…developed 1982

with automatic pressure filter cleaning

Presentation of the cross-oblique flow fan case in 1994

in INOX System WAIBL with air deflector plates.

Today still unique!

In 1993, WAIBL customized the cross-flow / oblique-flow construction to our regional as well as national and international requirements. The former cross-flowers were not suitable for our plant agriculture systems. It was not possible to drive with such a high construction on the public roads. Therefore we modified the fix cross flow construction into an adjustable mobile part. From now on it was possible to wrinkle half of the cross flow and fix fastened it on the container. Austria had other problems, the hail protection nets were installed to low for our high cross flow. The result was the new form of the cross flow / oblique flow, still current today.

Our cross-oblique flow is made of INOX with

numerable air deflector plates which are

adjustable in order to ensure an optimal air distribution.

Establishment drift-reducing nozzles

…first introduced in South Tyrol in 2007

To the already existing nozzles, a second nozzle assembly with drift-reducing nozzles is added. It is therefore possible, controlling it from the driver’s seat, to spray one side of the plant rows with conventional and the other side with drift-reducing nozzles.